Dry Sump, Single Turbo, VR38 swapped R34 Skyline

We’ve been so fortunate to be invited into a rather special build and offer our part design, prototype and manufacturing services to aid in the completion of “LEGIT” R34 Skyline.

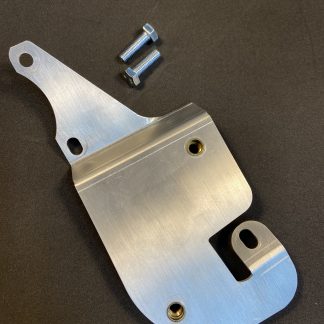

Above is the Crank angle sensor mount for the VR38VETT. As the engine has a dry sump fitted, the factory crank angle sensor mounting is removed and a new one must be fabricated. We took careful measurements of the bell housing area where the mount was to go, then modeled in Fusion 360 a part to suit, 3D Printed a prototype and test fitted. It wasn’t perfect the first time so we adjusted the model and prototyped 2 more parts before cutting it out of a 6061 Aluminum billet.

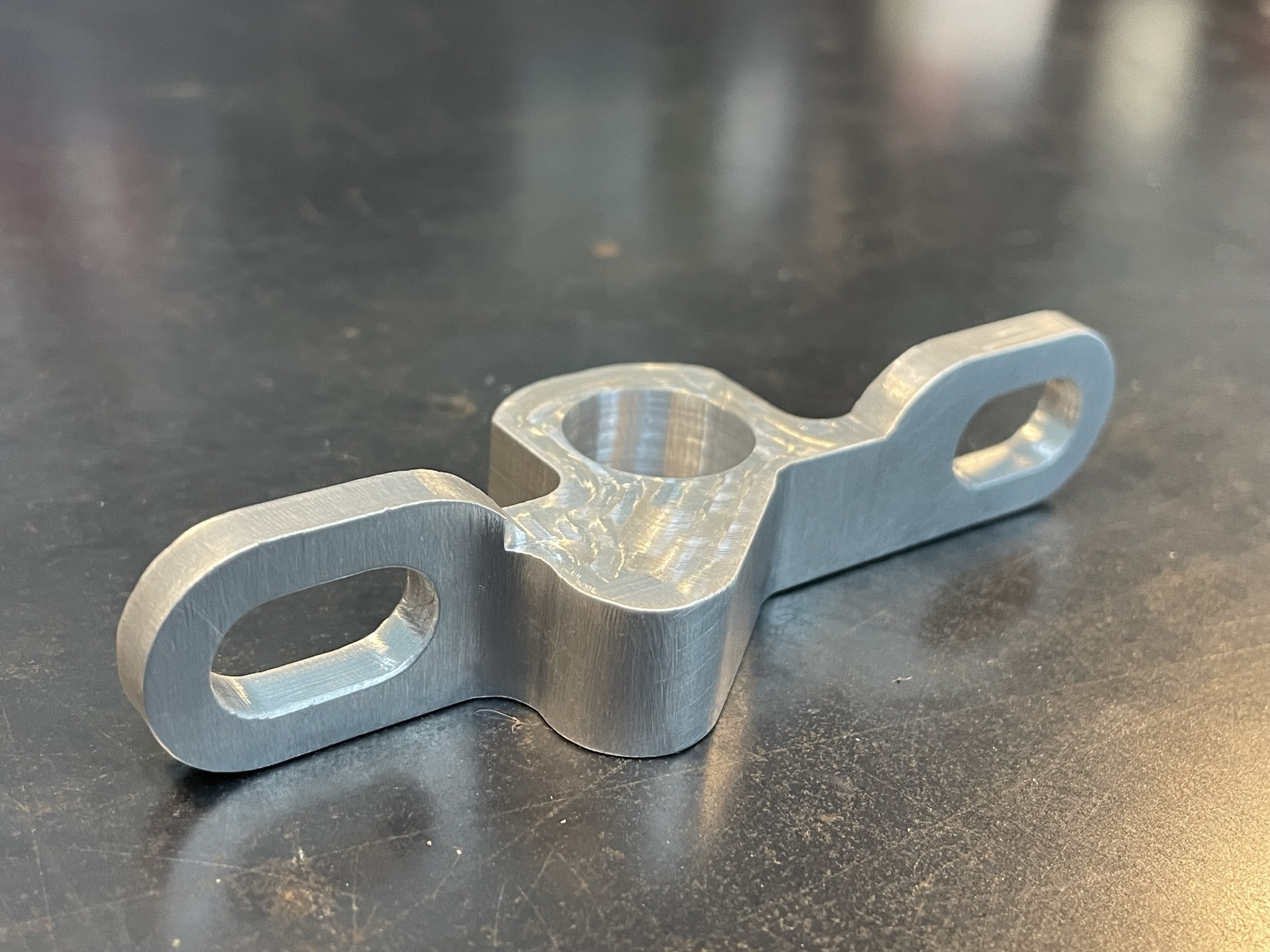

The other part we were commissioned to make was the alternator bracket. Because of the exhaust system that accommodates the single turbo conversion, a new LS style alternator was to be fitted. Test fitting the alternator was painful as space was tight in the engine bay when the engine and exhaust manifolds were fitted. So with the engine out of the car, we first 3D scanned the engine bay, then we 3D scanned the engine with the turbo manifolds fitted. Then we took those 3D scans and opened them together in Fusion 360. We then downloaded the CAD asset for a LS alternator and offered it up to the engine while the engine was in the vehicle virtually. With the alternator in place in CAD, we could then design an alternator bracket to suit.

Doesn’t look too pretty but that’s over 1gb of scan data!

We 3D printed the prototype bracket and it was a near perfect fit, just a millimeter here and there to adjust and it was ready to make out of aluminum.

The finished product looked great and will serve its purpose very well. We learned a lot about what our little mill is capable of and it’s only driven our desire to make more parts!