A lot of OEM vehicle engine management systems lack proper forms of engine protection, with nothing more than a “low oil pressure” light. Usually in cases where the light comes on, it’s too late for the engine. While engine protection isn’t as exciting as big turbos and bulk power, it is a crucial part of the longevity of your engine. Whether you have a stock engine or a fully built performance motor replacing an engine uses time and money.

There are multiple types of engine protections which will be detailed below.

Knock

Knock sensors are crucial to ensuring an engine is running safely. Knock sensors are used to measure noise coming from the engine, and are used to detect detonation or “ping”. Detonation is when fuel is ignited by the combustion and heat from the cylinder rather than the spark event. This ignition is not only at the wrong time during the engine cycle, but it also has a less smooth explosion. As detonation can very rapidly cause damage to pistons, valves, cylinders, and heads it is important that it is kept under control.

Oil Pressure

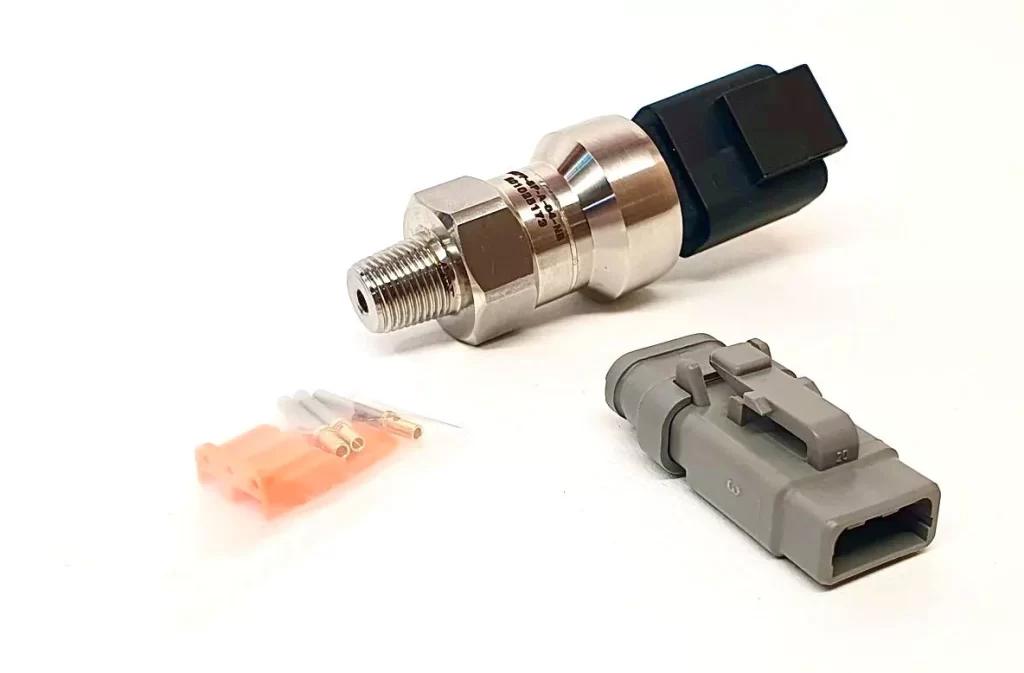

Oil pressure based protection is one of the most common types of engine protection. A sensor is used to monitor oil pressure and the ECU monitors this pressure.

Low oil pressure can result in catastrophic engine failure through spun bearings, damaged camshafts and thrown rods. It can also cause damage to attached components like turbochargers. For this reason, shutting off an engine which has low oil pressure can save vital components.

When racing the risk of oil starvation is increased due to high sustained load while engaged in high g-force cornering, braking, and accelerating. This can cause oil to surge away from the pickup and starve the engine of oil.

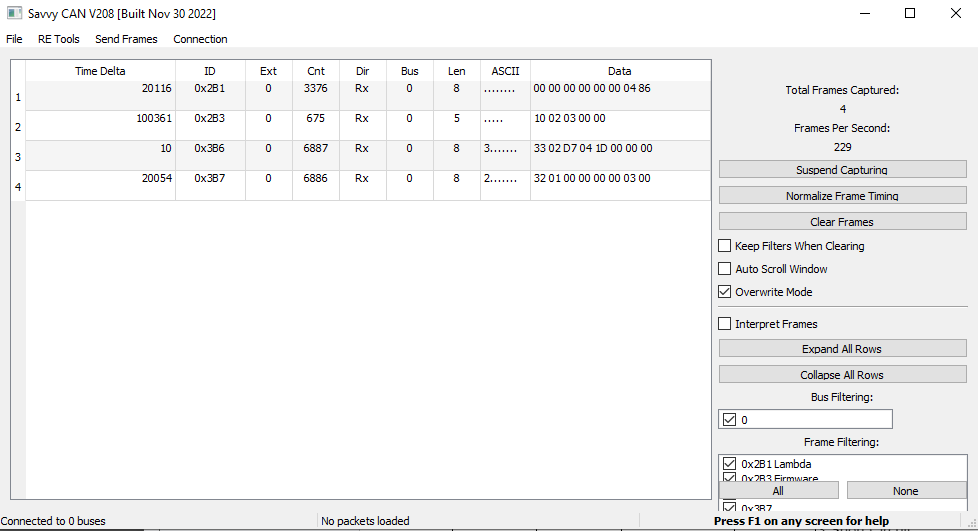

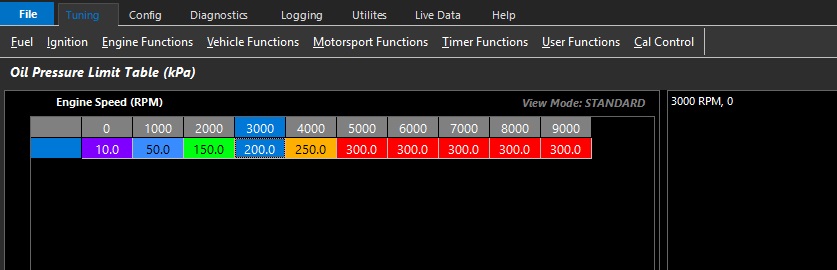

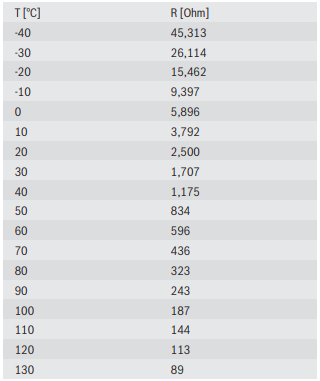

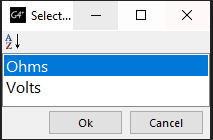

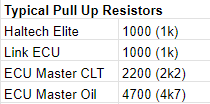

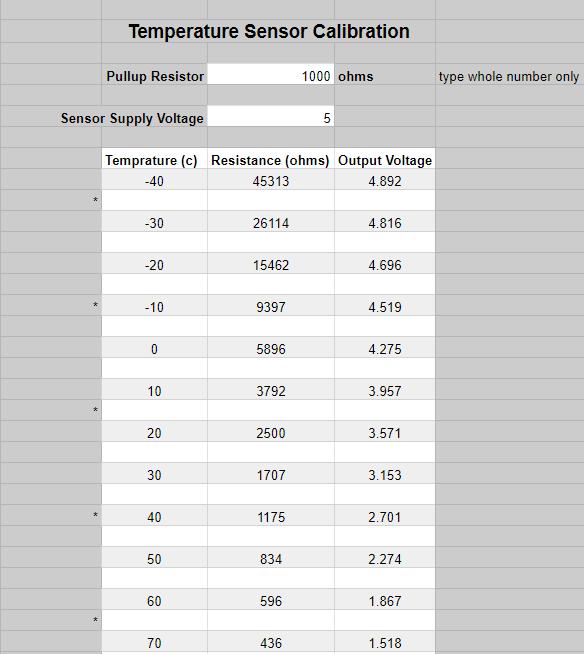

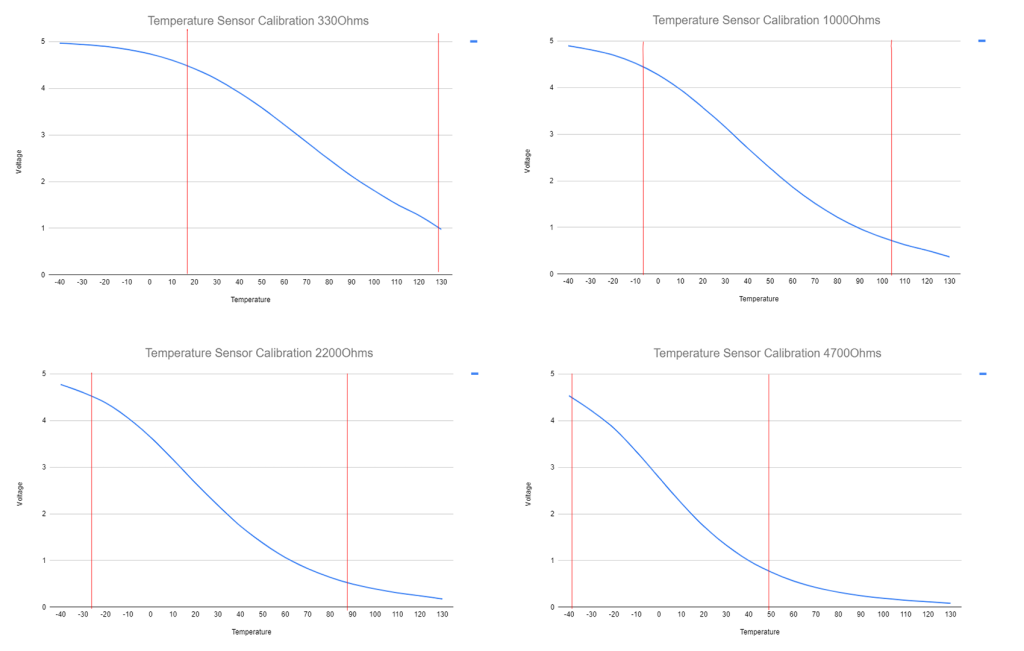

As oil pressure changes with engine rpm and temperature, these factors are often added as tables which change the engine cut activation. The following shows an oil pressure limit table based on rpm and pressure. If the engine is over the set RPM and sees an oil pressure lower than the one in the corresponding cell the limit will kick in, either limiting the engine to a low RPM or shutting off the engine entirely depending on how the limit has been set up.

Engine Temperature

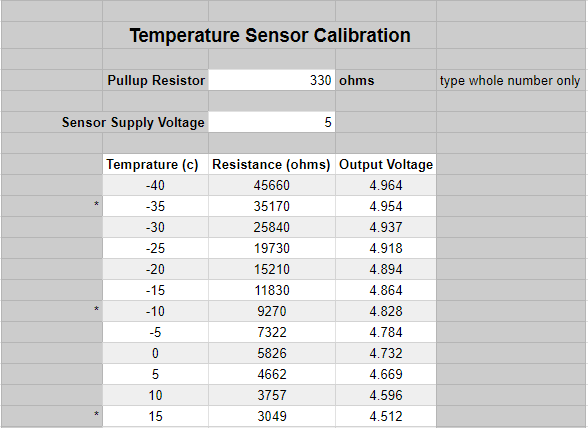

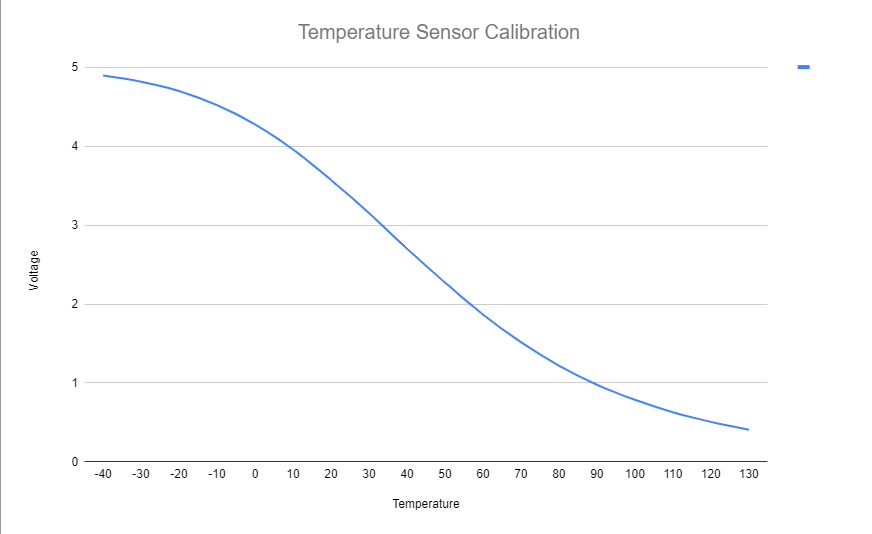

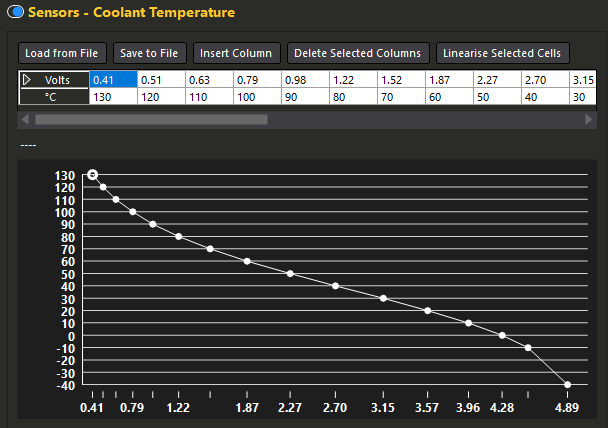

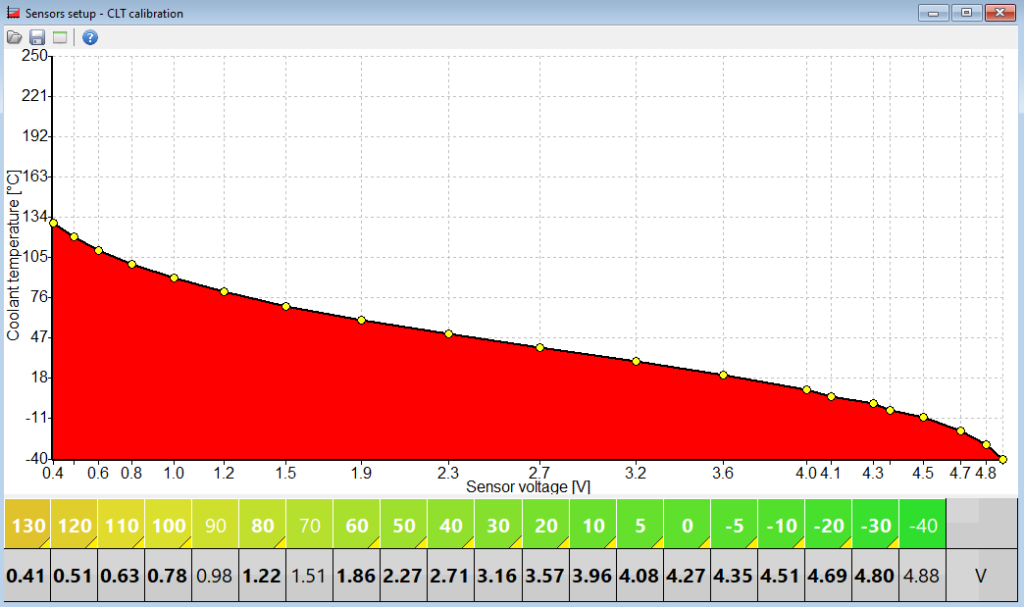

Engine temperature can be based off either coolant or oil temperature, and both are important to keep an eye on.

Oil temperature being too high will usually cause pressure problems before there are issues with the lubrication properties.

Coolant temperature is more commonly monitored, and is included in a basic form in most OEM cars. A high coolant temperature can cause blown head gaskets, warped and softened cylinder heads, and even seized pistons. Even at a lower level, a coolant temperature which is too high can lead to detonation.

For these reasons having engine temperature sensors which allow the ECU to limit RPM, or cut the engine if temperatures get too high can be the difference between an engine which will live to race another day, or an expensive lawn ornament.

Coolant Pressure

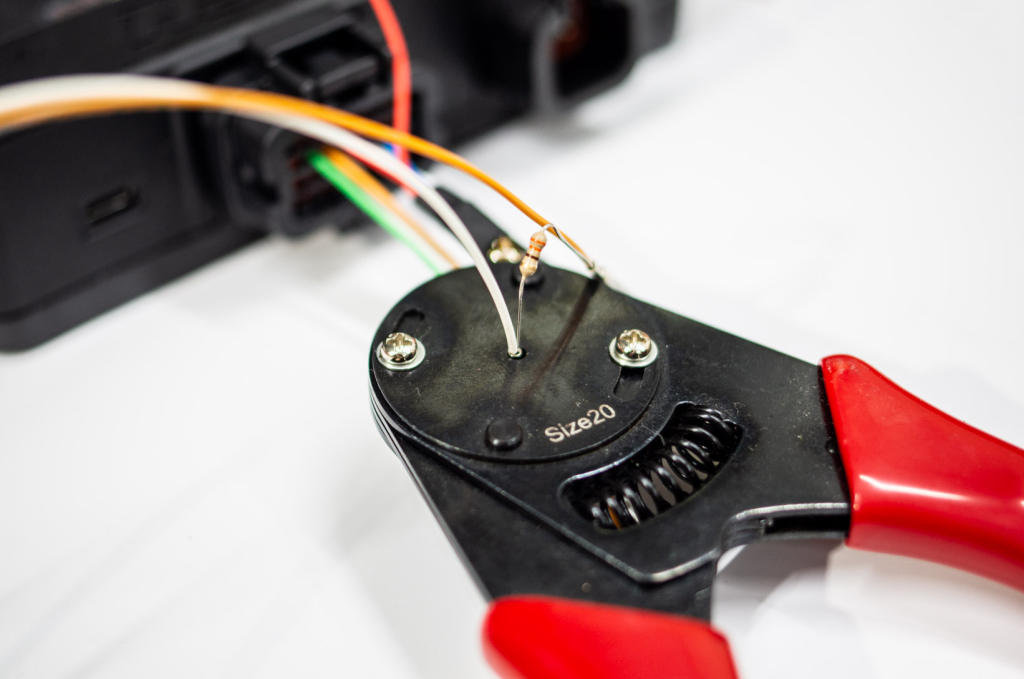

Coolant pressure is often related to coolant temperature, but it can also give an insight into other parts of the engine. . A coolant hose which has popped off will cause a drop in coolant system pressure, this can allow the driver to stop and fix the problem before the car overheats. Coolant pressure that is high can be a sign of high engine temperatures which make it more likely for a head gasket to blow due to warping of the mating surface. Irregular spikes in coolant pressures can also be a way to diagnose a blown head gasket as the escaping combustion gases raise the pressure in the coolant system. With the increasing prevalence of combined pressure and temperature sensors adding a coolant pressure sensor and corresponding cutoffs in the ECU is an easy way to monitor leaks within the coolant system.

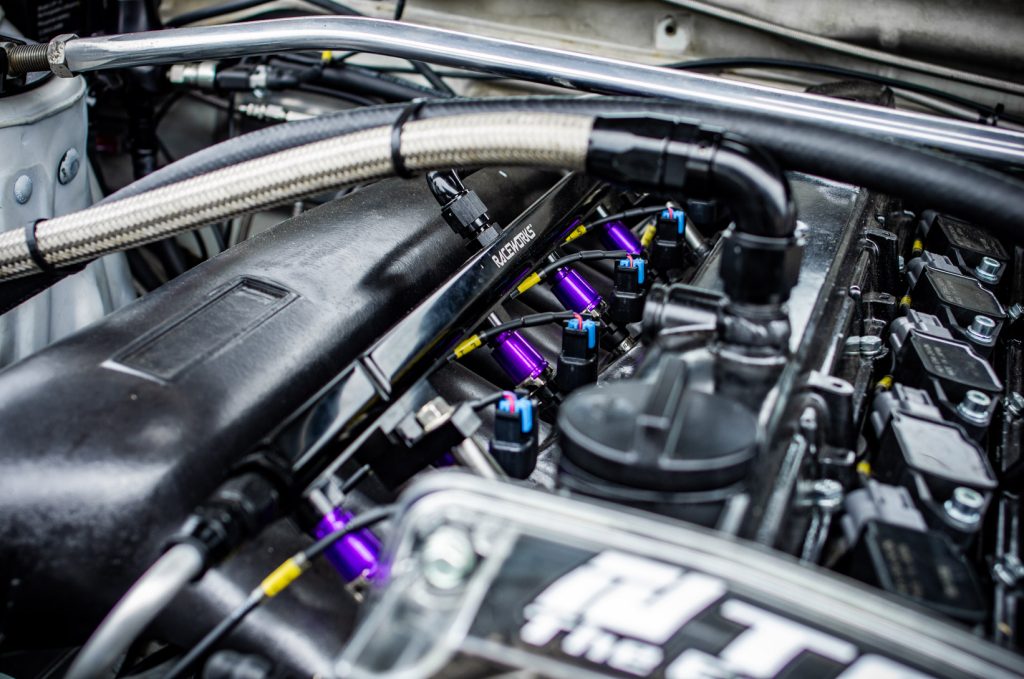

Fuel Pressure

Fuel pressure is another important factor as a drop in fuel pressure will usually lead to less fuel entering the cylinder than expected. This will cause the engine to be lean, which can cause damage. At lower RPM an engine running lean can just result in stalling, and poor performance, but under higher loads it can lead to detonation which may cause engine damage. Running lean will also cause higher cylinder temperatures which can also contribute to engine damage.

Fuel pressure can drop due to a failed fuel pump, or fuel pressure regulator. If this happens while the engine is under hard acceleration it can cause catastrophic engine failure. Fuel pressure isn’t always monitored as the base pressure is often set with a gauge, but most fuel pressure regulators have a bung which can be used for a sensor which can then be wired into the ECU.

EGT

High Exhaust Gas Temperatures (EGT) can cause damage to engine components, turbochargers, and the engine itself. In a diesel engine high EGTs are generally caused by the engine running too rich and is burning too much fuel compared to the amount of air it is getting.

Generally an EGT safety limiter is in place for diesel engines. The location of the EGT sensor(s) is important in ensuring your limiter numbers are set correctly.

Injector Duty Cycle

Injector duty cycle follows the same logic as fuel pressure with the same problems and dangers. If the injector duty cycle is at 100% then the injectors are effectively wide open. If the injectors are at 100% flow, the maximum amount of fuel is flowing through the injectors, it is then possible for more fuel to be necessary for combustion, but not enough is able to be provided. This will lead to a lean condition, and may cause engine damage. As the injectors are directly driven by the ECU it is usually fairly simple to add a form of injector duty cycle based protection to your ECU.

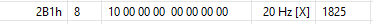

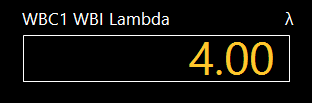

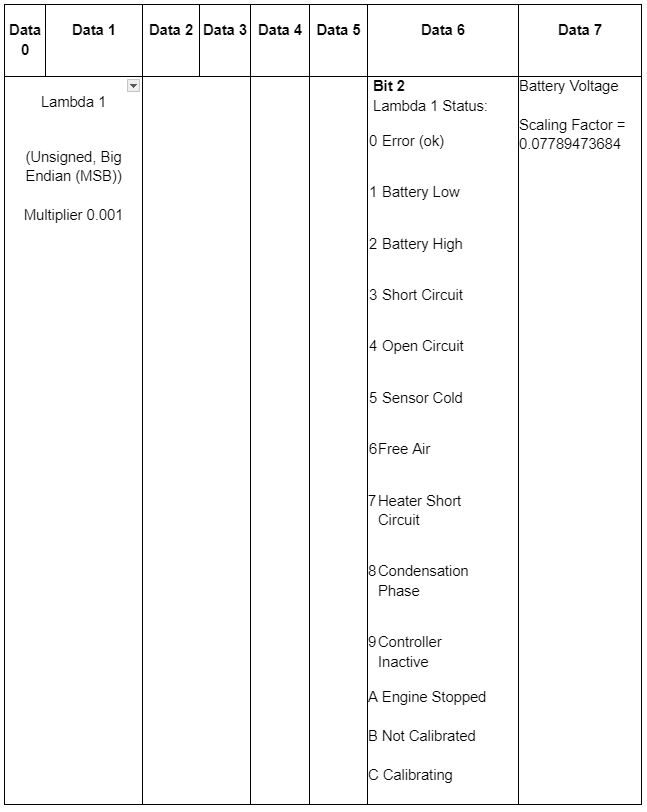

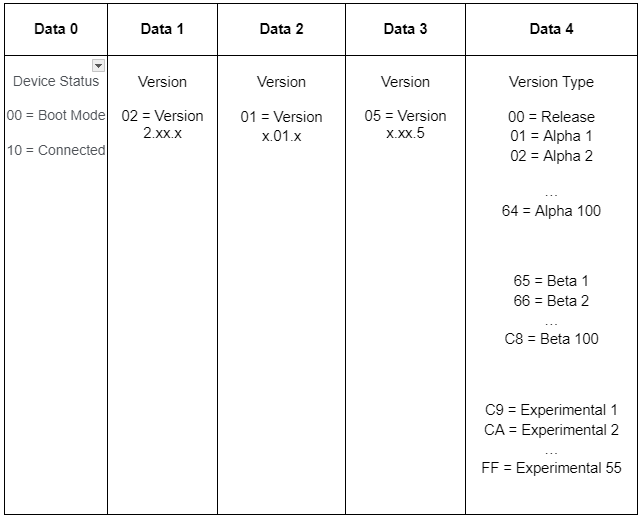

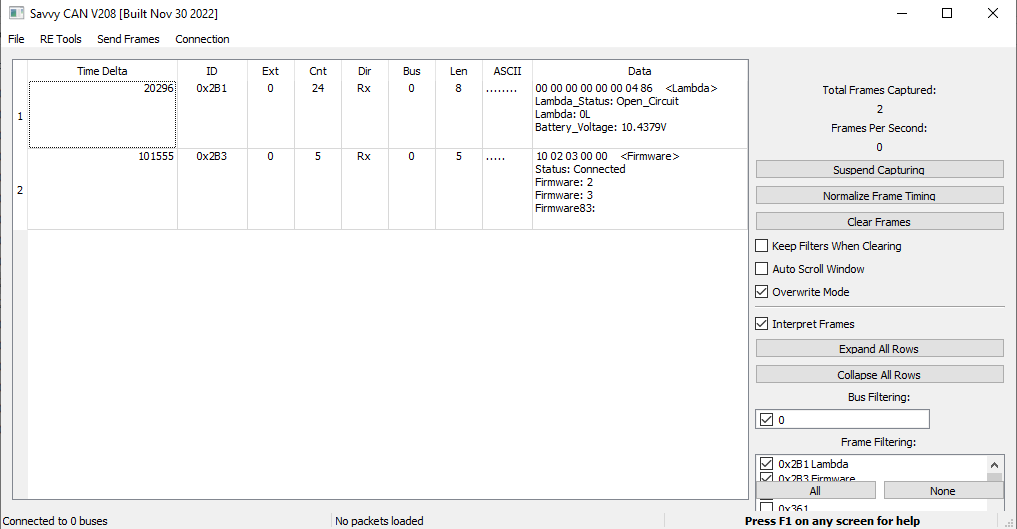

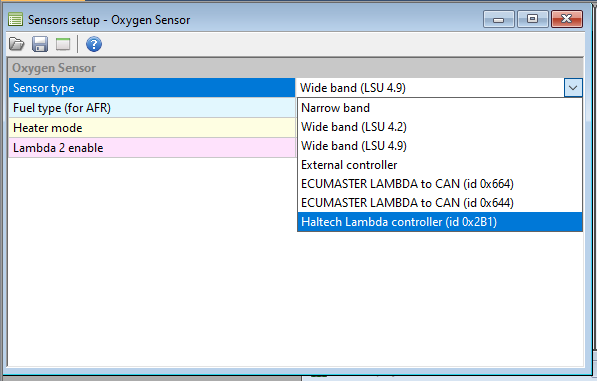

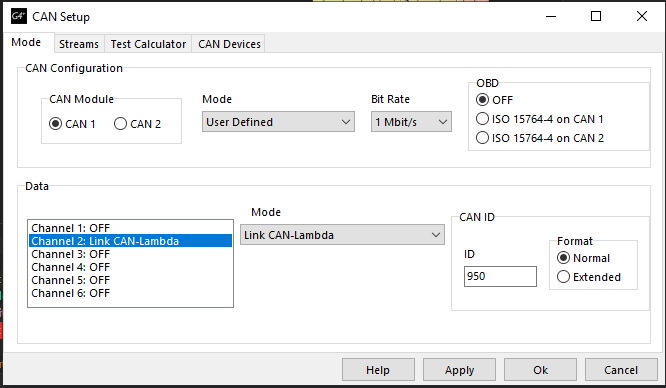

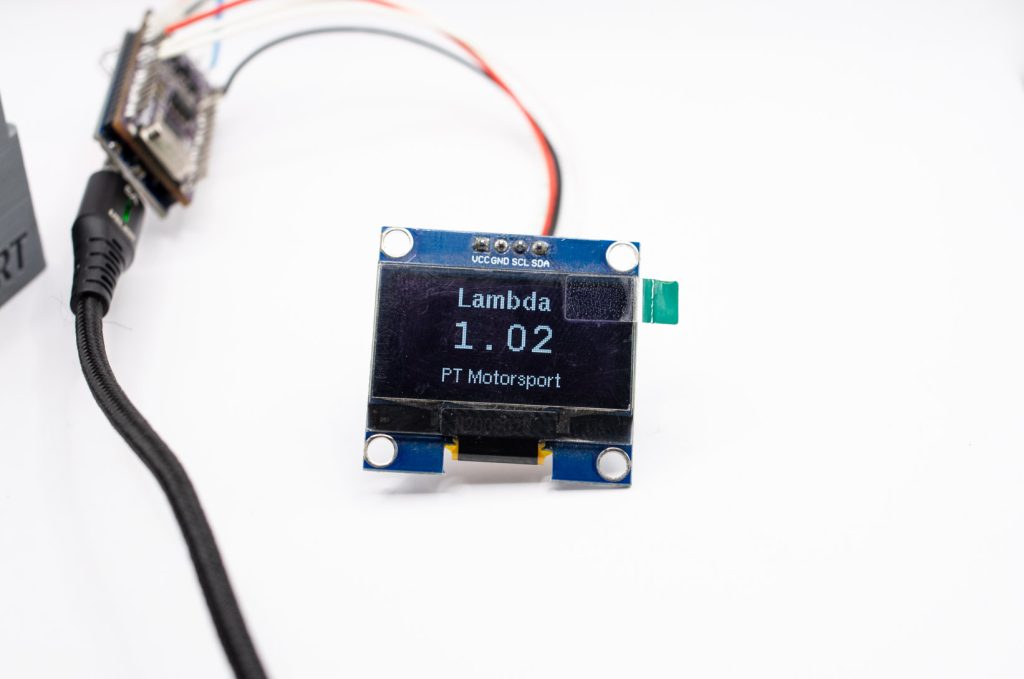

Lambda

Lambda (or AFR) protections also look at fueling, and can be another method to protect an engine from damage due to running lean, but Lambda protections can also be used to protect an engine from running too rich. As mentioned above, an engine which is running too rich can have EGTs which are too high. Using Lamdba based protections allows for a large scope of protection and can be used to prevent other issues. However, due to wideband sensors being positioned in the exhaust it is inherently a reactive system and while it will catch problems it may be too slow to effectively protect the engine from things like a sudden drop in fuel pressure. With that being said, as Lambda is generally monitored anyway it is not a particularly large extra step to set up when configuring your ECU.

Boost/MAP

While a properly tuned car is unlikely to overboost, especially to a level that causes engine or component damage, it is still possible for mechanical failures to occur. For example, a wastegate solenoid line can break, causing the turbo to continue building boost beyond where the wastegate should have opened. This can lead to increased cylinder pressures, causing bent rods, broken pistons, and lifted heads. For this reason a separate boost based engine limiter can be set up to limit the engine’s RPM if boost exceeds the set amount.

RPM

A general RPM limit is a great idea, as while an engine revving to the moon will sound incredible, it will likely only do that once before it starts to make some less incredible sounds. There is no hard and fast rule about what your RPM limit should be, but your tuner or engine builder should have a good idea of where to set the limit.

It is possible to have engine protection which is set up in an incorrect fashion. An ignition cut at high RPM can cause valve float due to high exhaust pressure from unburned fuel igniting in the exhaust manifold, on cars with shim-over-bucket style cam followers this can cause the shim to come out of its seat and cause engine damage. It is also important that the limits are set correctly. The location of a sensor can effect the figures which are read by the ECU. Or the numbers in the ECU might not be appropriate.

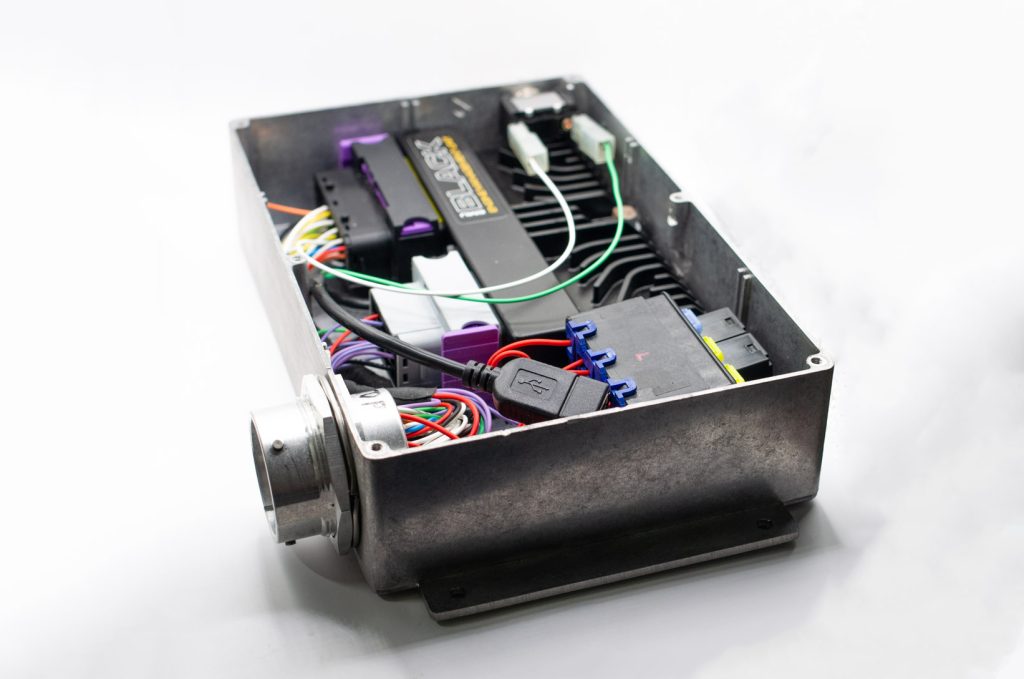

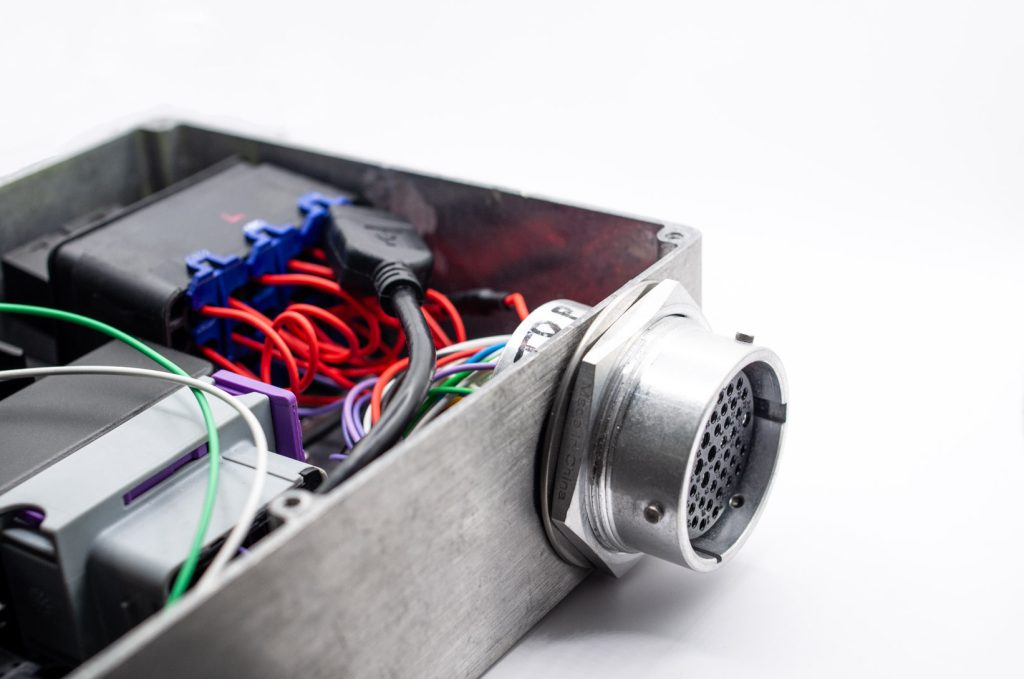

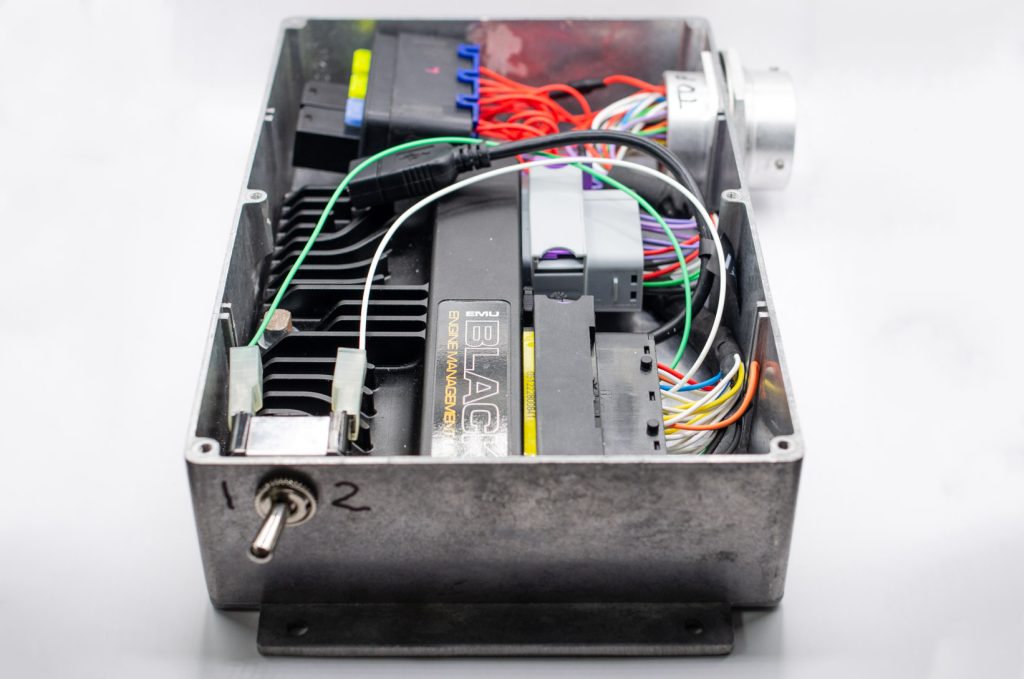

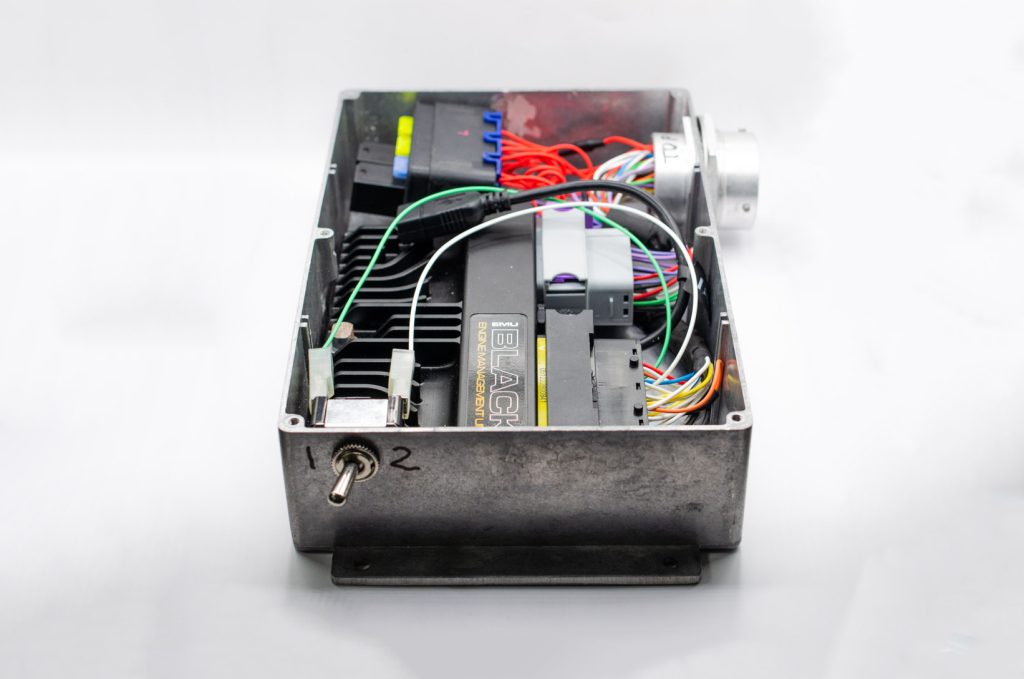

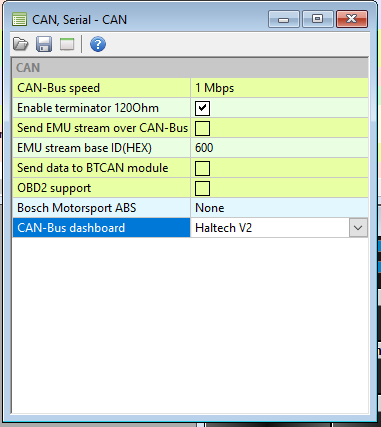

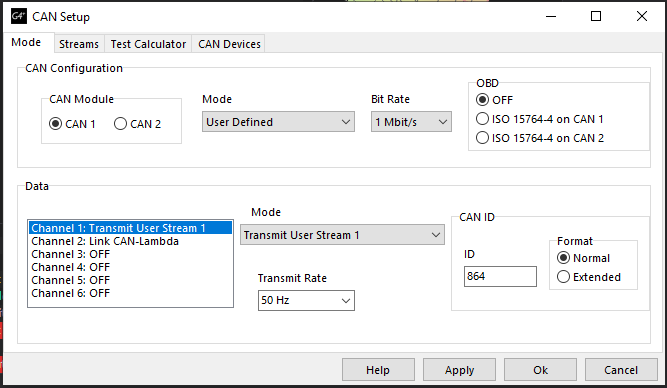

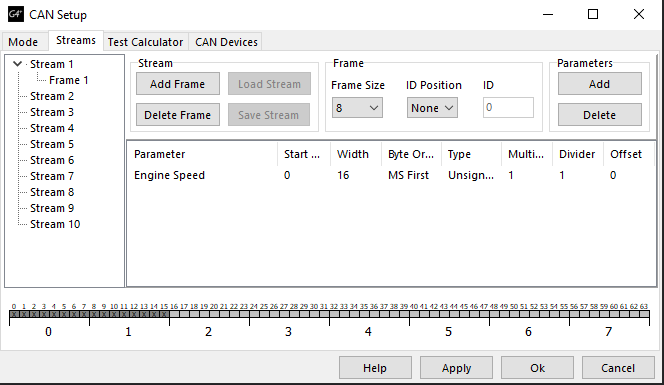

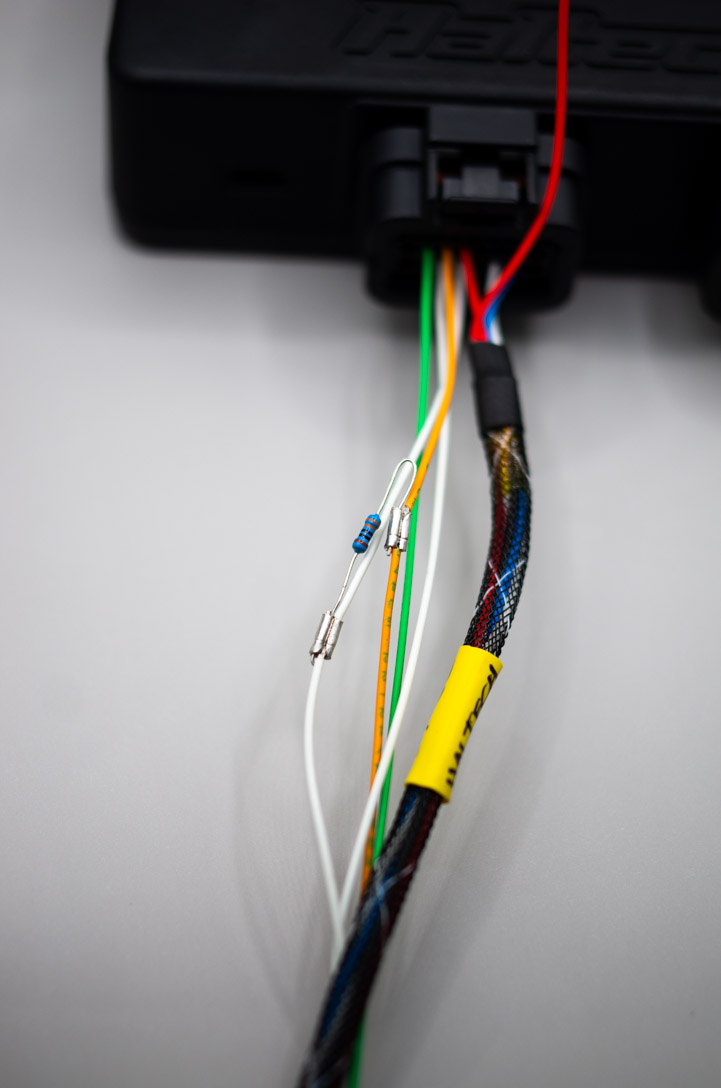

While not every aftermarket ECU will have the option to turn on all of these protections from a single tuning panel, many are able to be added through the use of User Defined tables. Engine protections also aren’t a magic bullet, and failures can still occur, but having as many safeties as feasibly possible will help ensure that smaller failures don’t turn into major ones. It is always important to talk to your wiring harness manufacturer, tuner, and engine builder about which forms of engine protection are best for you, and how best to implement them.